Yes you read the title correctly.

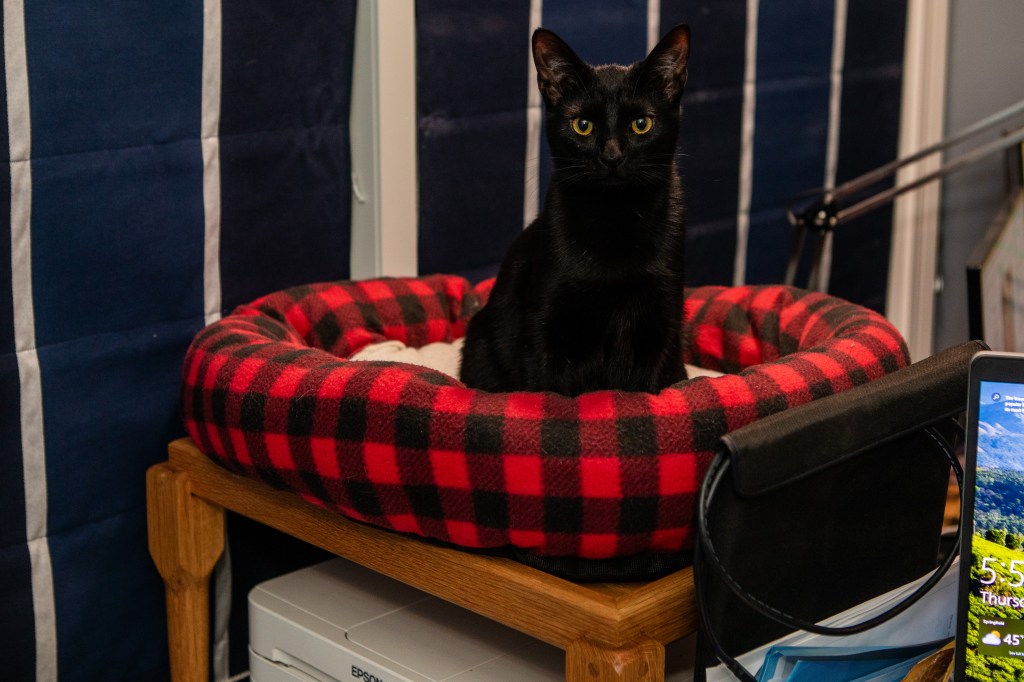

Last summer we got two new kittens and they love sitting in the window in the office. We turned a cardboard box upside down, over a printer/scanner, and put one of the cat beds on it so they could sit and enjoy the view.

After more than a few months, the cardboard began sagging and it was clear we need a more permanent solution.

Enter, the “table”.

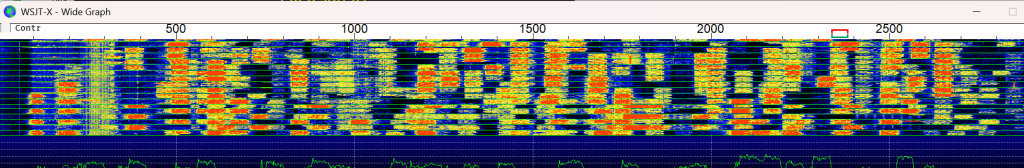

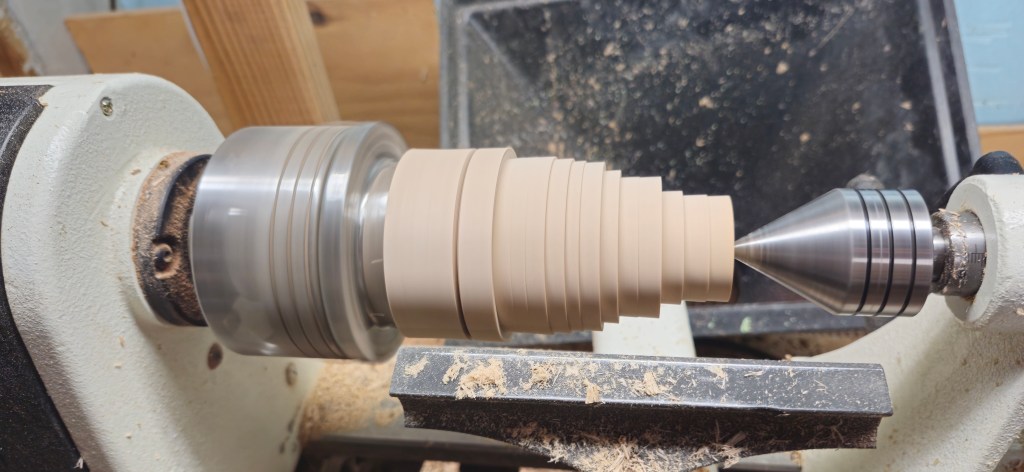

I used some White Oak boards I have and glued them up so I could attempt to make my own table legs. And I succesfully turned them!

The top of the table is more of a bin than a flat table top – a mitered frame a couple inches tall which will hold a typical pet bed. The sides are just tall enough to keep the bed from sliding straight off.

I’ve never done anything like a table before, so I wasn’t too fond of cutting mortises into my self-turned legs and decided to forgo an apron all together. I instead opted to embed the top bin into the legs, and pin them in with dowels.

It’s clearly a non-traditional configuration, but I like how it looks. It’s not just a small table, it’s something different.

The printer nestles undeneath nicely and, most importantly, the cats are enjoying their new digs.

Finished with two coats of natural tung oil.

Not too shabby.